| Availability: | |

|---|---|

| Quantity: | |

Laser Sheet Metal Fabrication: A Versatile and Precise Solution for Various Industries

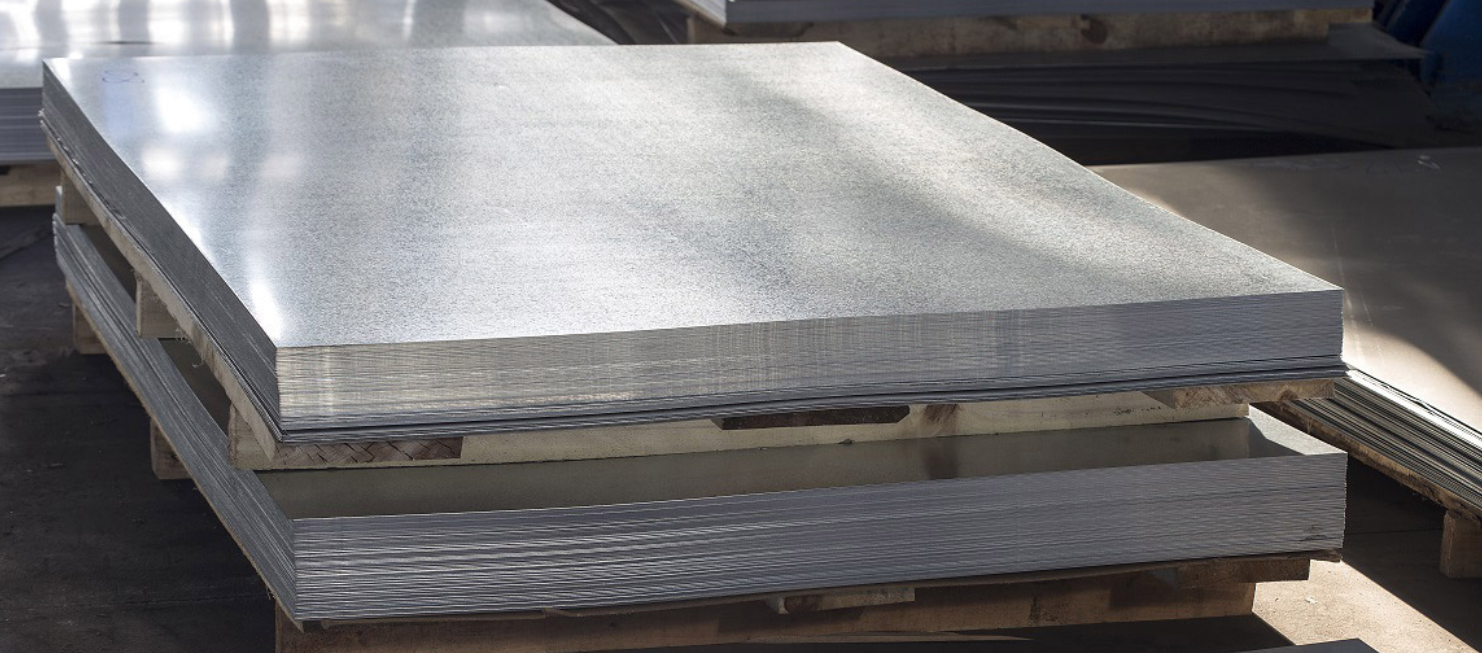

Laser sheet metal fabrication, also known as laser plate cutting, is a technique that uses a high power density laser beam to cut materials with different thicknesses. It can handle cold bonding plate and hot bonding plate up to 20.0 mm, and stainless steel up to 10.0 mm. At CBD Metal Co.Ltd, we use the German laser cutting machines (5030/3040/3030, a state-of-the-art equipment that ensures consistent accuracy and high quality control over the production process. Laser sheet metal fabrication is a versatile and precise solution for various industries, such as aerospace, automotive, medical, and more. Contact us today and let us show you how laser sheet metal fabrication can meet your needs.

Laser Sheet Metal Fabrication :A Non-Contact and High-Quality Method for Cutting Materials

Sheet metal laser cutting is a technique that uses a laser beam to cut sheet metals without making any physical contact with them. This method offers many advantages, such as high precision, speed, and flexibility. HSJ is a professional company of laser sheet metal fabrication that offers you high-quality sheet metal laser cutting service. Whether you need sheet metal parts for aerospace, automotive, medical, or other industries, CBD can deliver them with accuracy and efficiency. Contact us today and let us help you with your sheet metal laser cutting needs.

The utilization of CAD files for guiding the cutting designs from specific materials renders laser plate cutting a highly precise method. The sheet metal laser cutting process encompasses three distinct steps.

Step 1. Send us your artwork

You send us your artwork, and we will verify that the laser cutting machine and the material you want to cut are compatible. The machine can read vector strokes of any color and thickness, as long as they are thin enough for the laser beam.

Step 2. We set up the laser cutting machine

We place the material of your choice into our machine and set up the machine to cut your artwork. We customize the power, speed and frequency of the laser according to your material.

Step 3. We create your work

Then, the machine will follow the vector strokes and cut out the parts of your artwork with precision and accuracy.

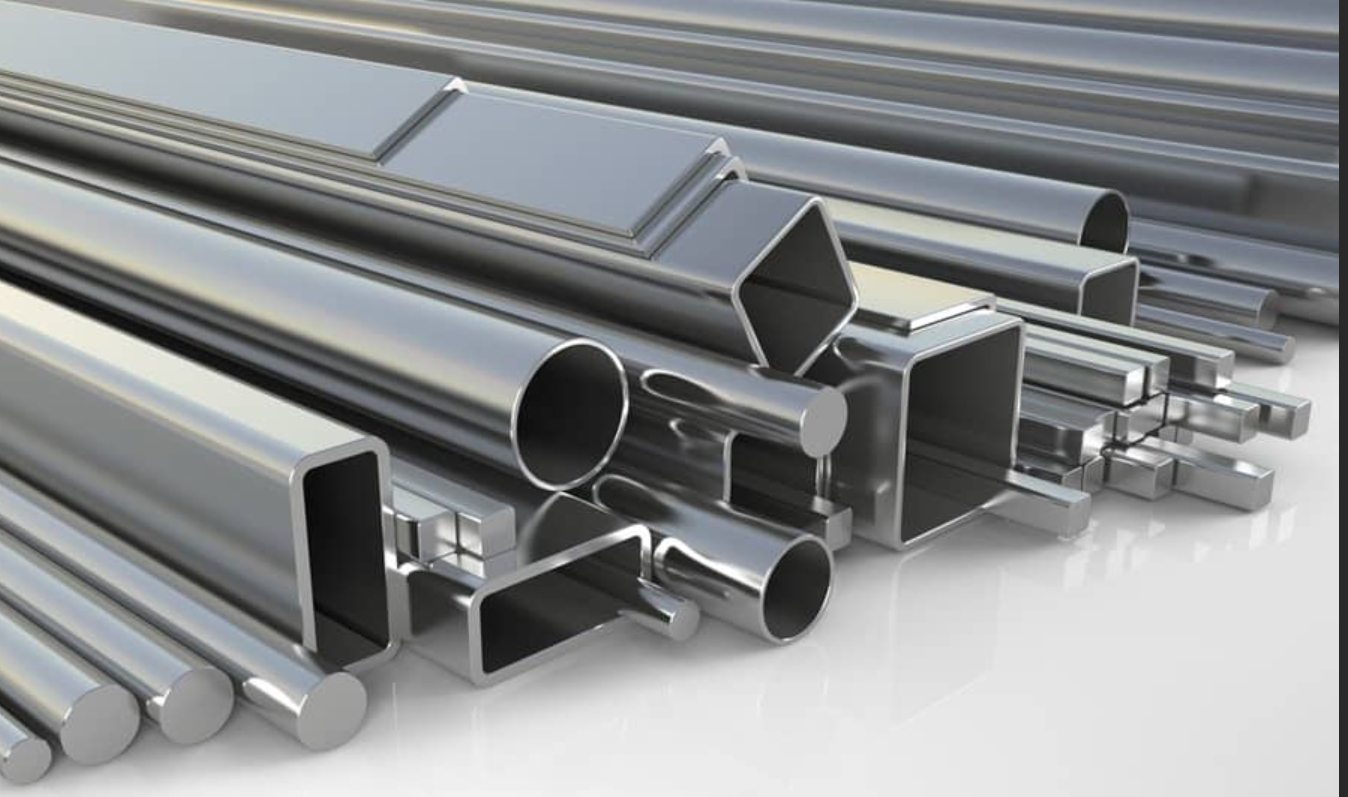

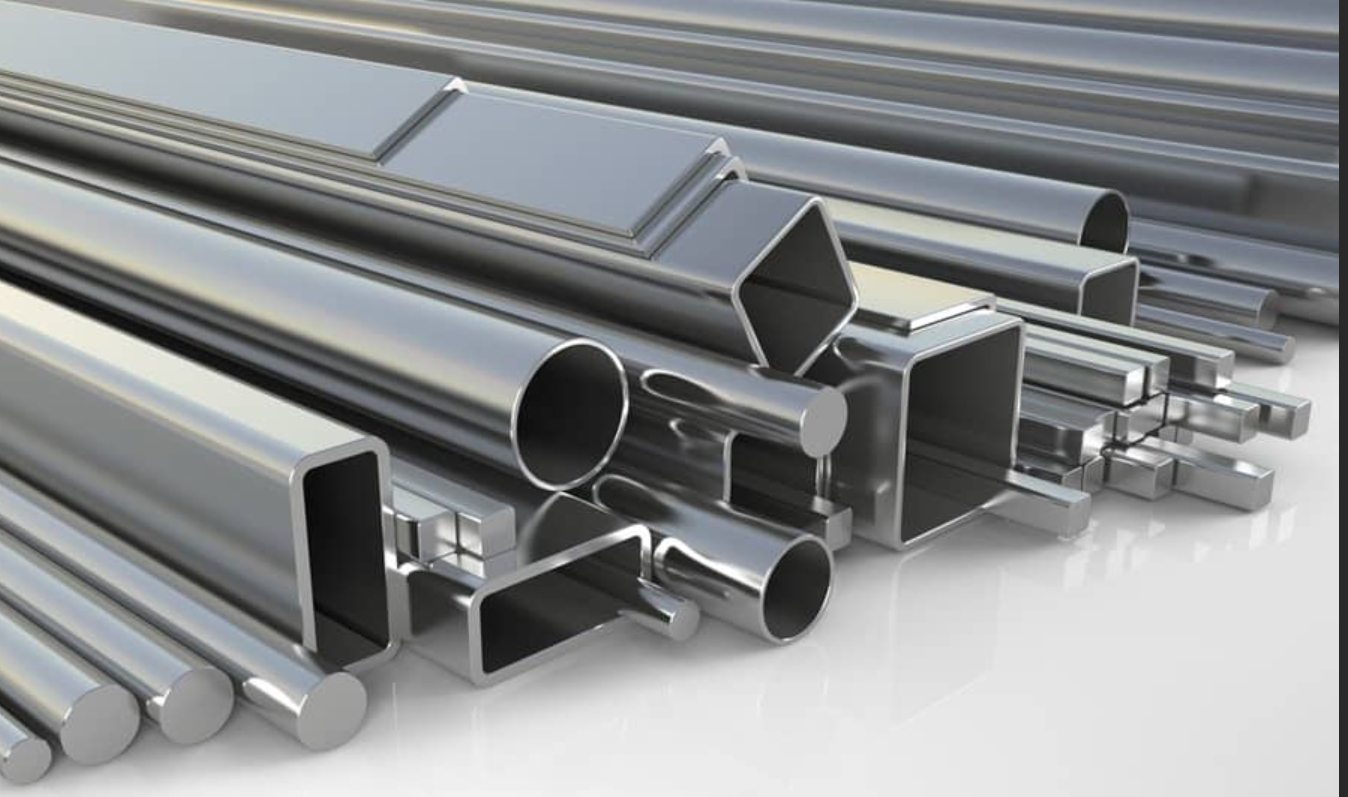

If you need a high-quality sheet metal laser cutting service, look no further than CBD Metal Fabrication Co., Ltd. We can handle a wide range of materials, such as SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel, and more. No matter what your sheet metal laser cutting needs are, we can deliver them with precision and efficiency. Contact us today and let us show you why we are the best choice for sheet metal laser cutting.

|  |  |

If you need to cut customized shapes from plates and sheets in a fast and efficient way, you can rely on CBD Metal Fabrication’s sheet metal cutting service. We use laser cutting, a non-contact and economical method that does not require expensive tools.

Why Choose Sheet Metal Laser Cutting?

You can enjoy a quick turnaround time, whether you need small or large batches of production.

You can benefit from our advanced numerical control machines that ensure accurate and precise cutting of metal shapes and blanks.

You can create complex and intricate designs with a small beam kerf that can cut thin metal into any shape.

You can avoid errors and reduce material waste with our reliable and controlled laser cutting process that adjusts the beam intensity, heat output and duration.

Contact us today and let us show you how sheet metal laser cutting can meet your needs.

CBD Metal Fabrication: Your Trusted Source for Custom Metal Duct Fabrication

At CBD Metal Fabrication, we offer a sheet metal cutting service that includes custom metal duct fabrication. We use precision laser cutting processes on sheet metal to meet your specific requirements.

Our CNC machines ensure the exact outcome you want. We offer a custom laser sheet metal fabrication service with constant support from our Technical Department that monitors the quality of sheet metal throughout the process.

If you need a dependable laser cutting manufacturer, CBD Metal is your ideal partner. We have our own designer team and professional service that will respond to you promptly. Please contact us anytime.

Computer Enclosure

We offer OEM Laser Cutting service for custom computer case sheet metal part, computer enclosure, computer host shell, computer chassis, and other electronic sheet metal parts.

Thickness: 0.1mm—20mm

Tolerance: ± 0.02 mm - 0.1 mm

Equipment: German (5030/3040/3030) laser cutting machine

Production capacity: 10-10000000pcs

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

Equipment: German (5030/3040/3030) laser cutting machine

Production capacity: 10-10000000pcs

Laser Sheet Metal Fabrication: A Versatile and Precise Solution for Various Industries

Laser sheet metal fabrication, also known as laser plate cutting, is a technique that uses a high power density laser beam to cut materials with different thicknesses. It can handle cold bonding plate and hot bonding plate up to 20.0 mm, and stainless steel up to 10.0 mm. At CBD Metal Co.Ltd, we use the German laser cutting machines (5030/3040/3030, a state-of-the-art equipment that ensures consistent accuracy and high quality control over the production process. Laser sheet metal fabrication is a versatile and precise solution for various industries, such as aerospace, automotive, medical, and more. Contact us today and let us show you how laser sheet metal fabrication can meet your needs.

Laser Sheet Metal Fabrication :A Non-Contact and High-Quality Method for Cutting Materials

Sheet metal laser cutting is a technique that uses a laser beam to cut sheet metals without making any physical contact with them. This method offers many advantages, such as high precision, speed, and flexibility. HSJ is a professional company of laser sheet metal fabrication that offers you high-quality sheet metal laser cutting service. Whether you need sheet metal parts for aerospace, automotive, medical, or other industries, CBD can deliver them with accuracy and efficiency. Contact us today and let us help you with your sheet metal laser cutting needs.

The utilization of CAD files for guiding the cutting designs from specific materials renders laser plate cutting a highly precise method. The sheet metal laser cutting process encompasses three distinct steps.

Step 1. Send us your artwork

You send us your artwork, and we will verify that the laser cutting machine and the material you want to cut are compatible. The machine can read vector strokes of any color and thickness, as long as they are thin enough for the laser beam.

Step 2. We set up the laser cutting machine

We place the material of your choice into our machine and set up the machine to cut your artwork. We customize the power, speed and frequency of the laser according to your material.

Step 3. We create your work

Then, the machine will follow the vector strokes and cut out the parts of your artwork with precision and accuracy.

If you need a high-quality sheet metal laser cutting service, look no further than CBD Metal Fabrication Co., Ltd. We can handle a wide range of materials, such as SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel, and more. No matter what your sheet metal laser cutting needs are, we can deliver them with precision and efficiency. Contact us today and let us show you why we are the best choice for sheet metal laser cutting.

|  |  |

If you need to cut customized shapes from plates and sheets in a fast and efficient way, you can rely on CBD Metal Fabrication’s sheet metal cutting service. We use laser cutting, a non-contact and economical method that does not require expensive tools.

Why Choose Sheet Metal Laser Cutting?

You can enjoy a quick turnaround time, whether you need small or large batches of production.

You can benefit from our advanced numerical control machines that ensure accurate and precise cutting of metal shapes and blanks.

You can create complex and intricate designs with a small beam kerf that can cut thin metal into any shape.

You can avoid errors and reduce material waste with our reliable and controlled laser cutting process that adjusts the beam intensity, heat output and duration.

Contact us today and let us show you how sheet metal laser cutting can meet your needs.

CBD Metal Fabrication: Your Trusted Source for Custom Metal Duct Fabrication

At CBD Metal Fabrication, we offer a sheet metal cutting service that includes custom metal duct fabrication. We use precision laser cutting processes on sheet metal to meet your specific requirements.

Our CNC machines ensure the exact outcome you want. We offer a custom laser sheet metal fabrication service with constant support from our Technical Department that monitors the quality of sheet metal throughout the process.

If you need a dependable laser cutting manufacturer, CBD Metal is your ideal partner. We have our own designer team and professional service that will respond to you promptly. Please contact us anytime.

Computer Enclosure

We offer OEM Laser Cutting service for custom computer case sheet metal part, computer enclosure, computer host shell, computer chassis, and other electronic sheet metal parts.

Thickness: 0.1mm—20mm

Tolerance: ± 0.02 mm - 0.1 mm

Equipment: German (5030/3040/3030) laser cutting machine

Production capacity: 10-10000000pcs

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

Equipment: German (5030/3040/3030) laser cutting machine

Production capacity: 10-10000000pcs

The Frequently Asked Questions (FAQs) Regarding Sheet Metal Laser Cutting